- This topic is empty.

-

AuthorPosts

-

2025-11-13 at 1:58 pm #63712

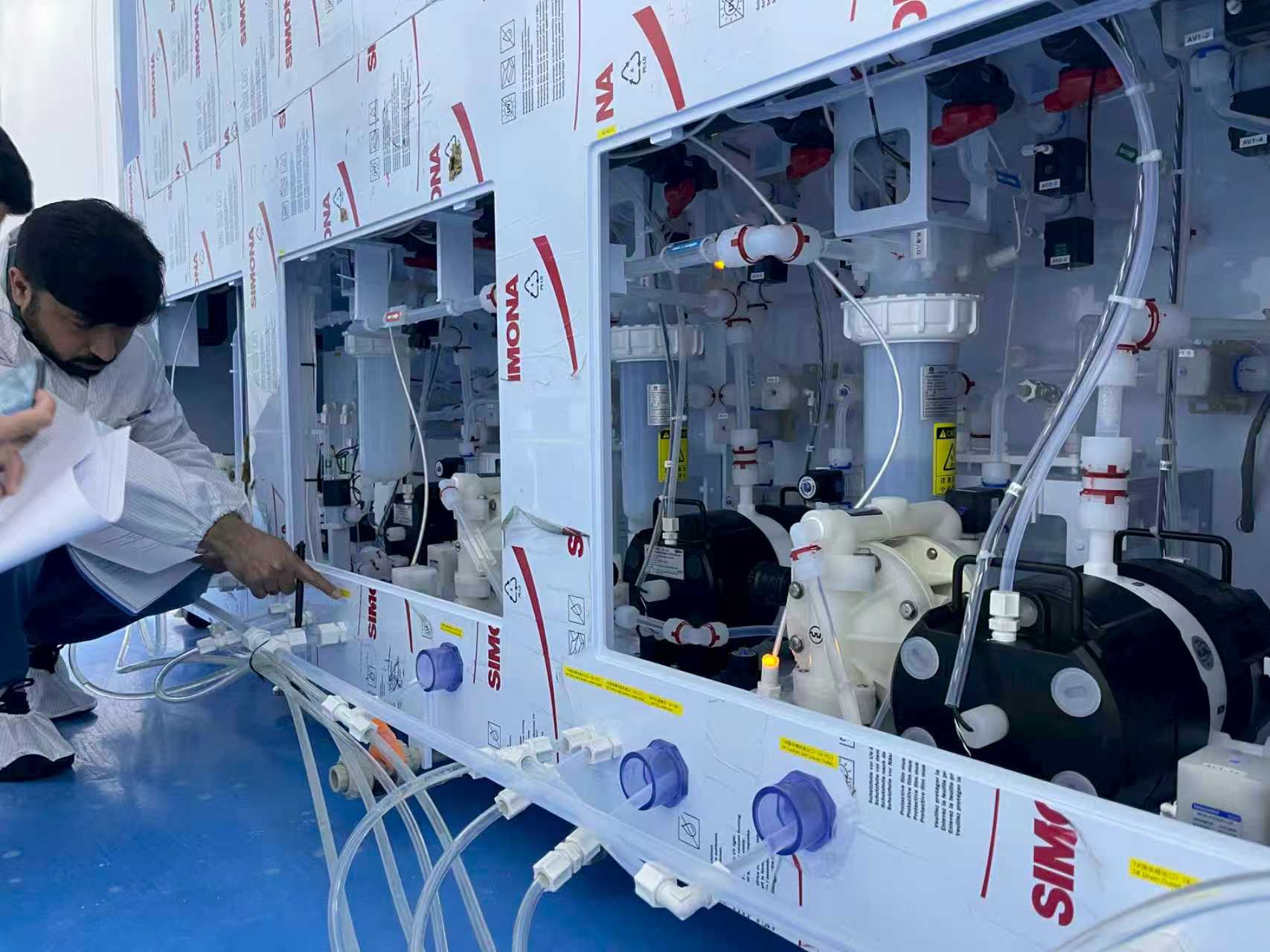

Recently, Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd. had the pleasure of hosting a delegation from Pakistan, who visited our facility to conduct a detailed on-site inspection of our wet etching and RCA wafer cleaning equipment. This visit not only highlighted the international competitiveness of our equipment but also laid a solid foundation for expanding our presence in the South Asian semiconductor market.

Client On-Site Inspection Highlights

During their multi-day visit, the Pakistani representatives toured our production and testing workshops, examining the wet etching and fully automated RCA cleaning machines from raw materials to final assembly.

The delegation observed detailed equipment demonstrations, focusing on key operational parameters and performance. They engaged with our technical team in in-depth discussions about system compatibility with local production lines, long-term operational stability, and after-sales support, ensuring that our solutions meet their specific semiconductor manufacturing requirements.

Spotlight on Core Equipment

The two inspected machines are flagship products in our wet process semiconductor portfolio:

1. Wet Etching Cleaning Machine

Designed for high-precision etching and surface cleaning of wafers, this equipment ensures nano-level material removal and ultra-clean surfaces.

Core Advantages:

-

Precision Etching Control: Optimized chemical concentration, temperature, and flow rates enable uniform nano-level etching, with rate deviation within ±2%.

-

High-Efficiency Cleaning: Integrated megasonic cavitation removes sub-micron particles (≥0.1µm) and organic residues; combined with a bidirectional spray system for 360° coverage on both wafer sides.

-

Smart Automation: Multiple process recipes can be executed with a single click; fully automated with fast single-wafer processing, compatible with 8” and 12” wafers.

Applications: CMP post-cleaning, pre-lithography preparation, metal layer etching, and advanced packaging processes.

2. RCA Cleaning Machine

Our RCA cleaning system is engineered for ultra-clean wafer surface treatment, removing organic, particulate, metal ion contamination, and native oxide layers sequentially.

Core Advantages:

-

Standardized Process Sequences: Adheres strictly to classical RCA cleaning protocols (SPM, DHF, SC1, SC2), ensuring optimal cleaning at each step.

-

Stable and Reliable System: Corrosion-resistant tank materials, dual-layer leak prevention, comprehensive alarm systems, and error-proof design for consistent long-term performance.

-

Flexible Configuration: Available in manual, semi-automatic, and fully automatic modes, improving efficiency and reducing operational costs.

Applications: Critical in IC manufacturing, silicon wafer production, MEMS fabrication, and other semiconductor surface pre-treatment applications.

Collaboration and Future Prospects

The visit from our Pakistani partners served as a comprehensive review of Xinruiwei Semiconductor Technology’s technical expertise, production quality, and management standards. The clients expressed high appreciation for the precision engineering, intelligent control, and exceptional performance of our equipment across multiple key semiconductor processes.

As the global semiconductor industry continues to grow, Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd. remains committed to innovation and quality. Our solutions, developed and manufactured in China using European components, offer the highest quality standards and reliable delivery. From laboratory-scale prototypes to industrial batch production, we provide customized solutions for both lab and industrial applications, helping customers worldwide achieve energy-efficient, high-precision, and automated wet process cleaning solutions.

We look forward to deepening collaboration with partners in Pakistan and other regions, jointly advancing semiconductor manufacturing technology and applying innovative solutions for the next generation of high-tech devices.

http://www.wafera.com

Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.