- This topic is empty.

-

AuthorPosts

-

2025-05-31 at 10:13 pm #62579

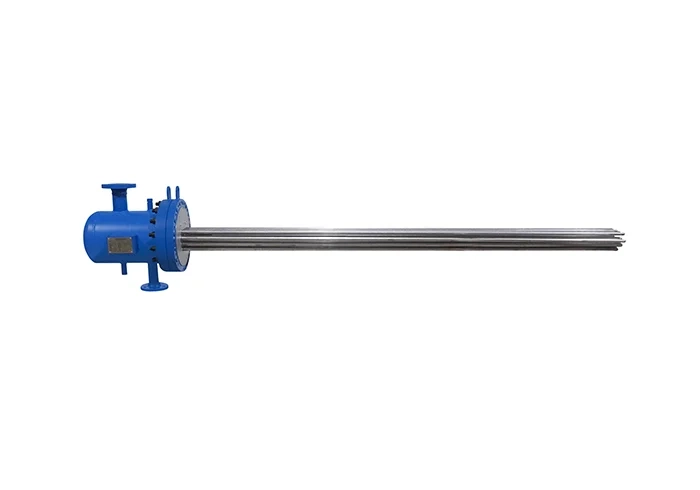

In the realm of high-temperature, corrosive processing environments—particularly in the chemical, semiconductor, and aerospace industries—thermal equipment must deliver not just performance, but endurance. Among the elite class of heating technologies that can operate reliably under such harsh conditions is the bayonet tantalum heater. Known for its corrosion resistance, thermal uniformity, and structural integrity, this specialized heater is a cornerstone in high-purity acid baths, chemical vapor deposition (CVD) systems, and other critical operations. This article Qiwei provides an in-depth analysis of the bayonet tantalum heater, focusing on its design principles, materials engineering and operational performance. The goal is to offer an expert-level understanding of why this heater is not just preferred, but often irreplaceable in environments where failure is not an option.

Design and Materials Engineering of Bayonet Tantalum Heater

Tantalum as a Base Material

The defining feature of the bayonet tantalum heater is its construction from tantalum, a refractory metal known for its extraordinary resistance to strong acids such as hydrochloric, nitric, and sulfuric acids. With a melting point above 3,000°C and a passive oxide layer that resists corrosion even in aggressive acidic environments, tantalum ensures long service life and consistent thermal output. Unlike traditional metal heaters that suffer rapid degradation in acidic baths, the bayonet tantalum heater can maintain full functionality for years without significant loss in performance. This makes it ideal for high-purity acid heating applications in semiconductor fabrication and specialty chemical synthesis.

Structural Configuration

The "bayonet" design refers to the heater's structural geometry: a tubular form factor with sealed or semi-sealed ends, optimized for immersion into process tanks. These heaters typically consist of an inner heating element encased within tantalum tubing or sheathing, sometimes accompanied by tantalum or tantalum alloy fins to increase surface area and heat transfer efficiency. This structure facilitates easy vertical or horizontal insertion into tanks, offers rapid heat-up times, and allows for maintenance-free operation in enclosed and difficult-to-access systems. The modular design of bayonet tantalum heaters enables customization based on tank geometry, process volume, and heating profile.

Operational Performance of Bayonet Tantalum Heaters

Uniform Heat Distribution

Bayonet tantalum heaters are engineered to deliver highly uniform heat distribution across their active surfaces. The combination of high thermal conductivity and custom-fabricated heating coils ensures that process fluids receive consistent heating, avoiding hot spots and temperature gradients that can compromise process integrity. This is especially critical in semiconductor etching and cleaning processes, where even slight temperature deviations can affect wafer quality. The bayonet tantalum heater's ability to maintain thermal uniformity under continuous operation is a decisive factor in its widespread industry acceptance.

Rapid Thermal Response and Control

Because of its direct immersion design and high-efficiency electrical heating element, the bayonet tantalum heater achieves rapid thermal response. This facilitates precise temperature control during ramp-up, soak, and cool-down phases of processing. In systems equipped with PID controllers and real-time thermal feedback, the heater integrates seamlessly to provide tight thermal regulation. This responsiveness is essential in batch and continuous-flow processes where timing and thermal consistency directly affect product yield and purity.

Exceptional Corrosion Resistance

No other heating element offers the same level of chemical inertness as a bayonet tantalum heater. It remains unaffected by most mineral acids at high concentrations and temperatures. This property significantly reduces contamination risk and heater failure due to corrosion, which are common issues with alternative materials such as stainless steel or quartz. This corrosion resistance is not merely a material advantage but a process enabler, allowing systems to run uninterrupted for extended periods without replacement or acid purification. For industries focused on ultra-high purity and long-term ROI, this makes the bayonet tantalum heater a strategic investment.

The bayonet tantalum heater represents a pinnacle of thermal engineering tailored to the most demanding chemical and semiconductor environments. Its unmatched resistance to corrosion, thermal uniformity, structural strength, and compatibility with advanced control systems make it an essential asset in any process requiring precision and durability under extreme conditions. For industries that operate on the cutting edge of performance and reliability, the bayonet tantalum heater is not merely a heating element—it is a critical infrastructure component that ensures product quality, operational continuity, and regulatory compliance.

https://www.tnztn.com/Tantalum-Bayonet-Heater-F-3-5.html

http://www.tnztn.com

Wuxi Qiwei Nonferrous Technology Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.