- This topic is empty.

-

AuthorPosts

-

2025-11-13 at 1:57 pm #63710

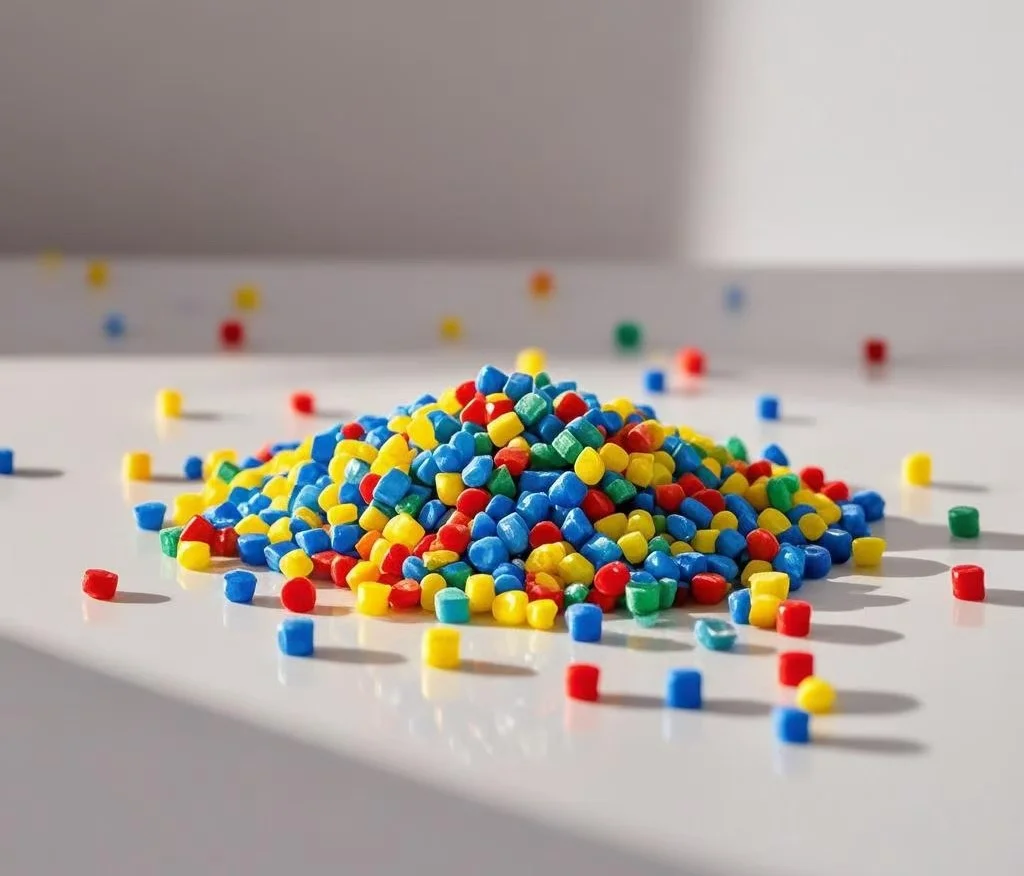

In today’s highly competitive plastic manufacturing industry, achieving precise color control, material uniformity, and production efficiency is essential for success. Color masterbatch equipment plays a central role in this process—ensuring consistent coloration, optimal material dispersion, and reduced production waste.

As a leading enterprise committed to driving innovation in the machinery industry, Jiangsu Kaifeng Xinye Intelligent Equipment Co., Ltd. has developed advanced color masterbatch production and processing equipment widely used in foam extrusion, plastic compounding, and other manufacturing fields. Let’s explore how modern color masterbatch equipment enhances the efficiency and consistency of plastic manufacturing.

1. Achieving Uniform Color Dispersion

One of the most critical aspects of plastic manufacturing is color consistency. Inadequate dispersion of pigments or additives can lead to uneven coloration, product rejection, and increased material waste.

Modern color masterbatch equipment utilizes precision screw designs and optimized mixing technology to ensure uniform pigment distribution throughout the polymer matrix. This results in smooth, vibrant, and consistent color performance across every batch.Jiangsu Kaifeng Xinye’s intelligent mixing systems are engineered to deliver high shear dispersion and low energy consumption, striking the perfect balance between quality and efficiency.

2. Improving Production Efficiency and Throughput

Traditional color mixing methods often require long processing times and manual adjustments, leading to delays and inconsistency. In contrast, automated color masterbatch systems enable continuous feeding, precise dosing, and real-time control, which significantly improves production speed.

By integrating smart temperature control systems and digital monitoring, Kaifeng Xinye’s equipment minimizes downtime and human error—allowing manufacturers to achieve higher output rates and lower operating costs. This automation-driven process ensures smooth, efficient, and repeatable production cycles.

3. Reducing Material Waste and Energy Consumption

Sustainability is now a key focus across all manufacturing sectors, and color masterbatch production is no exception. Efficient masterbatch equipment helps reduce material waste by optimizing pigment usage and improving mixing accuracy.

Advanced control systems ensure that each batch uses the exact required amount of pigment and polymer, reducing excess consumption and preventing costly reprocessing.Kaifeng Xinye’s innovative equipment design also emphasizes energy efficiency, using intelligent heating and cooling systems that lower power usage while maintaining precise process control—helping manufacturers achieve both environmental and economic benefits.

4. Enhancing Product Quality and Performance

Beyond color consistency, high-quality masterbatch equipment contributes to better mechanical and thermal properties in plastic products. Uniform dispersion prevents pigment clumping and enhances the final product’s surface appearance, strength, and durability.

Whether used in automotive components, packaging materials, or construction products, Kaifeng Xinye’s color masterbatch equipment ensures superior color stability, gloss, and transparency, helping manufacturers meet strict quality standards and customer expectations.

5. Intelligent Automation for Greater Reliability

The rise of Industry 4.0 has transformed how manufacturers manage production. Jiangsu Kaifeng Xinye integrates intelligent automation and digital control technologies into its equipment, allowing remote monitoring, data tracking, and predictive maintenance.

This not only enhances production reliability and traceability but also enables manufacturers to adjust process parameters instantly to maintain optimal performance. Such smart systems ensure consistent quality, reduced downtime, and better resource management, giving businesses a strong competitive edge.

Conclusion

Color masterbatch equipment is no longer just a tool for mixing pigments—it’s a key driver of efficiency, precision, and quality in modern plastic manufacturing. Through intelligent control, uniform dispersion, and energy-efficient design, these machines help manufacturers achieve better results with lower costs.

http://www.kaifengmachine.com

Jiangsu Kaifeng Xinye Intelligent Equipment Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.