- This topic is empty.

-

AuthorPosts

-

2025-10-29 at 2:44 pm #63591

In the global shift toward renewable energy, solar power stands as one of the most efficient and sustainable solutions. Yet, even the most advanced photovoltaic systems lose efficiency when covered by dust, pollen, or bird droppings. Regular cleaning is essential, but traditional methods—manual wiping or water spraying—are inefficient and costly. This is where the solar panel cleaning roller brush comes into play.

The solar panel cleaning roller brush offers a practical, time-saving, and environmentally friendly way to maintain solar panels at peak performance. By automating and streamlining the cleaning process, it ensures panels operate close to their rated efficiency throughout the year. In this blog post, WANLV, as a high performance solar rooftop cleaning brush manufacturing factory, will share the working principle of solar panel cleaning roller brush.

Working Principle of Solar Panel Roller Brush

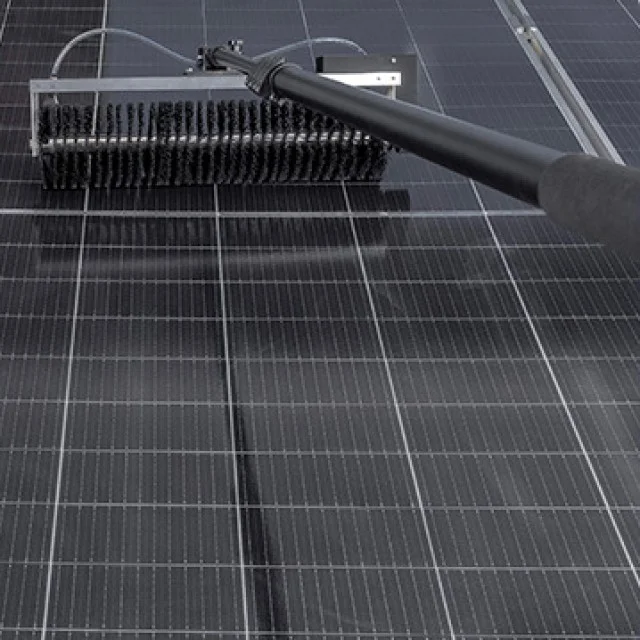

A solar panel roller brush operates on a simple yet highly effective principle: rotating bristles powered either manually, electrically, or via a built-in motor sweep away accumulated debris without damaging the panel surface. The design ensures consistent contact pressure, allowing for thorough cleaning across large installations without scratching the glass or disrupting delicate coatings.

These brushes are often made with soft nylon or microfiber filaments, which are durable enough to remove stubborn grime yet gentle on panel surfaces. The roller is typically attached to a lightweight aluminum handle or telescopic pole, allowing operators to reach high or wide areas effortlessly. In automated systems, motorized roller brushes can move across entire panel rows autonomously, saving time and labor costs.

How Solar Panel Cleaning Roller Brush Improves Efficiency

The correlation between panel cleanliness and energy output is undeniable. A layer of dust as thin as 1 millimeter can reduce efficiency by 5% to 10%. Over time, this loss compounds into significant energy waste. Using a solar panel cleaning brush roller ensures maximum sunlight absorption by removing the contaminants that block solar cells from capturing light.

Regular cleaning with a roller brush also helps maintain thermal performance, preventing uneven heating or “hot spots” caused by dirt patches. In areas prone to sand, ash, or industrial pollutants, integrating a cleaning brush into maintenance schedules can lead to substantial long-term gains in productivity and return on investment.

Different Types of Solar Panel Cleaning Roller Brushes

The market offers several variants of roller brushes for solar cleaning, each catering to specific operational needs and installation scales:

-

Manual Roller Brushes:

Ideal for small or residential systems, these brushes attach to extension poles and can be operated by a single person. They are lightweight, cost-effective, and require minimal setup. -

Electric Roller Brushes:

These are powered by batteries or plug-in motors, making them suitable for medium-sized installations. Electric brushes reduce physical effort and provide a consistent brushing motion, improving cleaning uniformity. -

Automated or Robotic Roller Brushes:

For large-scale solar farms, fully automated systems equipped with roller brushes traverse the panels autonomously. They often include sensors and AI-based navigation, ensuring complete coverage with minimal water use.

Each type of solar roller brush addresses the specific challenges of solar maintenance, from accessibility to water conservation.

Eco-Friendly Cleaning: Water and Energy Savings with Roller Brushes

A standout benefit of the solar panel roller cleaning system is its environmental efficiency. Traditional cleaning methods can waste thousands of liters of water, particularly in arid regions where water scarcity is already an issue.

Modern roller brushes minimize water usage by requiring only a fine mist to loosen dirt before brushing. Some designs even feature dry cleaning capability, using static or mechanical friction to remove dust without any water at all. Additionally, when integrated with robotic platforms powered by solar energy, these brushes make maintenance nearly carbon-neutral.

This combination of energy self-sufficiency and water efficiency aligns perfectly with the sustainability goals of solar energy systems, creating a closed-loop of green innovation.

Key Considerations When Choosing Solar Panel Cleaning Roller Brush

Selecting the right solar panel brush roller depends on several factors:

-

Panel Layout and Size: Larger installations benefit from motorized or robotic options, while smaller systems can be managed with manual tools.

-

Bristle Material: Ensure the bristles are non-abrasive yet durable enough for outdoor conditions. Nylon and microfiber are common choices.

-

Mobility and Reach: Telescopic handles or lightweight carbon fiber poles enhance accessibility.

-

Water Supply Compatibility: Some roller brushes integrate water-fed designs that deliver controlled moisture during cleaning.

-

Maintenance and Cost: Consider spare parts availability, energy use, and the long-term cost of operation.

Properly matching the brush to the installation ensures efficiency, longevity, and safety for the panels.

Conclusion

The solar panel cleaning roller brush represents more than just a maintenance accessory—it is a critical component of a high-performance solar system. By ensuring consistent cleanliness, these tools protect long-term energy yields, reduce operational costs, and uphold environmental sustainability.

As the renewable energy industry continues to innovate, efficient and eco-friendly cleaning technologies will play an increasingly vital role. Whether through manual tools for small arrays or autonomous robots for mega-scale plants, roller brushes are redefining how the world keeps its solar panels shining at full power.

-

-

AuthorPosts

- You must be logged in to reply to this topic.